Home / English / Articles & Interviews / Articles / Screen printing brings the premium effect

Screen printing brings the premium effect

Exceptional label designs implemented economically

By Dieter Finna

Exceptional label design functions like a Trojan horse. Amazing and attractive to look at, it is uncompromisingly designed for conquest. Brands are increasingly focusing on screen printing for labels, as it offers a wide range of options for attracting customers with its extraordinary, exclusive design effects. A visit to Gallus in the screen printing division in Herisau (Switzerland) demonstrates everything that is possible with screen printing.

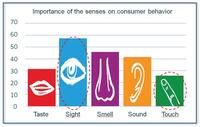

What makes screen printing effects so attractive is clearly demonstrated by the human sensation of stimulus. When shopping, visual perception is, at 58% the most important aspect of our perception of stimulus. If a product comes within reach, the sensory experience can be increased by a further 25% through the sense of touch. Because both senses provide decisive buying impulses at the point of sale, the label and packaging design of high-end market segments rely on so-called premium effects, which specifically address these senses. Rotary screen printing offers the widest range of options for implementing these in terms of printing technology. This explains the constant growth of screen printing, often in new areas of application.

Market segments

Typical market segments in which rotary screen printing is used are, above all, labels in the "Personal Care" and "Beverage" application segments, in this case mainly in Wines & Spirits and Premium Water. But other segments such as "Household" and "Food" also have impressive examples. Clear-on-clear applications, especially with drinks, are experiencing a strong upsurge. They allow label design to play with opacity and transparency, combined with coloured stimuli and tactile elements. The examples given in this section show impressive "no-label-look" or "clear-on-clear" labels that print service providers can only achieve with a high proportion of screen-printing.

Exceptional label designs

For example, the "no label look" label LIFEWTR is printed in 12 colours. Due to the extraordinary opacity of white screen printing, consumers can also read the brand logo through the back of the transparent bottle. The colourful allure of the graphics also radiate from this perspective, especially in combination with transparent elements. Tactile elements on the surface also lend the bottle exceptional tactile appeal. An absolutely extraordinary label designed for a transparent plastic water bottle.

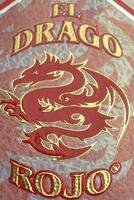

The vodka label "El Drago Rojo" also thrives on its haptic elements, which are produced via a transparent varnish on the Clear-on-Clear label. The non-transparent motif components are backed with white screen printing, the rich red and gold applied by screen printing.

The metal relief effect on the Infusion Care tube laminate is created by the so-called "metallic doming". For this purpose, an adhesive layer is applied by rotary screen printing, over which a hot foil is laminated with a rubber roller. Print images can thus be produced even on plastic films with a permanent metallic relief.

"Strongly on the rise, especially in the beverage segment, are clear-on-clear applications."

Heinz Brocker, Gallus Business Unit Screen Printing

The right screen printing unit

Screen printing, with its wide range of embellishing options, complements other printing processes in label printing. As a rule, these are flexographic and offset printing, in some cases also book and gravure printing. This means that the required screen printing units in the printing sequence of narrow web machines must be able to be used where they are necessary for the implementation of the design. This varies from job to job. A decisive factor for the economical use of screen printing is therefore the rapid change of printing processes during the execution of an order. In label printing, machine systems in which the screen printing units are located on the same process level as the printing units of other printing methods have proven particularly useful. This has the advantage of extremely short process change times and web paths. Gallus for example develops an appropriate screen printing unit for each machine type as an integrative solution that uses the printing function of the basic machine. The development team has adapted them to the drive system of the various machines by means of different stencil rings on which the printing plates as welded screen tubes are bonded.

The required screen printing units must be able to be used in the printing order where they are required to implement the design.

If screen printing is used, two screen printing units are usually integrated in a label printing machine. There are applications in which up to six, in exceptional cases even up to ten screen printing units are used. In all cases, the focus is always on fast set-up times, low start-up waste and achieving a high printing speed.

Screen printing plates

For decades, Gallus Ferd. Rüesch AG has been supporting label convertors around the world in the implementation of unusual label designs. The different effects in screen printing require a comprehensive plate portfolio. Gallus already has the third generation of Screeny screen plates on the market, which continues to evolve in terms of reusability and service life.

One feature of plate selection is its rigidity, which significantly influences shelf life. Once this has been defined, the plate types differ in plate thickness, which is decisive for the transferred ink layer as well as the resolution. At the same time, the mesh size controls the possible fineness of the motif. Thus, halftone printing and delicate lines, combinations of line and solids, coarse solid motifs or even relief printing with tactile elements can be implemented.

"Gallus has the most comprehensive screen printing plate portfolio on the market."

Heinz Brocker, Gallus Business Unit Screen Printing

Premium is also conquering mass products

Much of what makes up extraordinary label design is similar to the approach in Troy. At the marketplace, today called the "Point of Sales", it is important for the labelled product to attract the attention, to offer the consumer something visually impressive. If this is successful, the surprise effect follows. Extraordinary label designs in the second step provide the premium effect, through tactile elements or special design effects. The incentive to buy is already there.

The fact that well-known or developing brands rely on this is not surprising. It is even more ingenious when used in segments where you do not expect it. Recently, a large Swiss retailer gave their bread packaging a premium screen-printed touch. An indication that screen printing can also conquer mass products when it comes to standing out from the crowd.

About the Author

Dieter Finna graduated as a printing engineer at the Bergische Universität Wuppertal. In his many years at Flint Group, he held versatile positions in the printing plate and ink business. He has a broad expertise in the printing and packaging industry and in 2016 he founded pack.consult, a platform for content marketing and packaging printing consulting.

News

The doors to FESPA Global Print Expo and European Sign Expo 2021, Europe’s leading exhibitions for speciality print and signage, will open in just a few days (12 – 15 October 2021 at the RAI, Amsterdam, The Netherlands). For the first time since Spring 2019, FESPA is welcoming its communities of print service providers and sign makers back to a live event, with a focus on bringing colour back after 18 extraordinary months for these industries.

Elitron will be showcasing the following: Kombo SD+ 31.20: multi-function, digital cutting table with full range of cutting tools for all your digital finishing requirements; Kombo SDC+ 31.20: multi-function, flexible, digital conveyor cutting table with full range of cutting tools for both roll and rigid media and others Elitron Innovations for 2021.

Under the heading ‘New beginnings. New opportunities’, Agfa celebrates the gradual ‘reopening’ of the world and the occasion to present its updated range of inkjet printing solutions live to the European graphic industry at FESPA in Amsterdam (12-15 October).